History of Eddy Current Testing

Between 1775 and 1900, scientists such as Coulomb, Ampère, Faraday, Ørsted, Arago, Maxwell, and Kelvin developed and documented most of the knowledge we have today about magnetism and electromagnetism. These principles form the foundation of modern electromagnetic non-destructive testing (NDT) methods.

- 1820: Ørsted discovers the magnetic field generated by an electric current.

- 1824: Arago observes that the oscillations of a magnetized pendulum are strongly dampened when near a non-magnetized conductive material.

- 1831: Faraday formulates the principles of electromagnetic induction.

- 1873: Maxwell consolidates these findings in his two-volume work, whose equations remain fundamental in electromagnetism research.

For a long time, these discoveries were not applied in industrial inspection. However, starting in the 1930s, significant progress was made, particularly by German scientist Dr. Friedrich Förster.

Dr. Förster conducted pioneering tests and established the theoretical foundations of eddy current testing. He also designed specialized equipment for this technique.

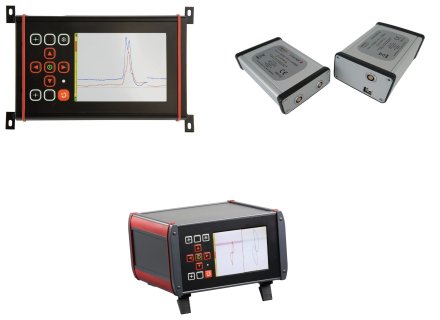

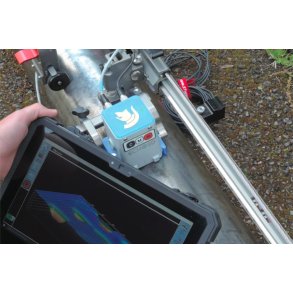

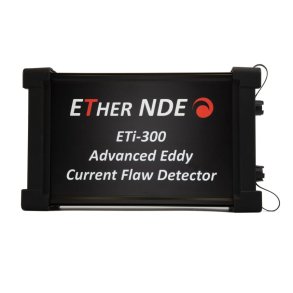

Since the early innovations of Dr. Förster, eddy current testing technology has rapidly advanced. Between 1975 and 1985, there were notable developments in both equipment design and application.

From the mid-1980s onward, the first microprocessor-based instruments appeared on the market, enabling inspection data storage, reference defect records, and indication logging during analysis.

_copy (1) (1)/assets/images/header/trustpilot.png)