Product Description

Determining crack depth using the potential probe method is based on measuring the electrical resistance between two points on the surface of a metallic workpiece.

The Crack Depth Meter RMG 4015 measures crack depths in steel, iron, and austenitic materials and can also be used for cracks in copper, brass, and aluminum, as well as most non-ferrous metals. Special probes are available for measuring inclined cracks. The RMG 4015 is an ideal supplement to PT or MT testing.

Specifications

- Measuring range: 0 mm to 99.9 mm in electrically conductive materials like iron or steel, 0 mm to 12 mm in aluminum, copper, brass

- Crack depth measurement is also possible on inclined cracks in ferromagnetic materials

- Special probes are available for complexly shaped surfaces and hard-to-reach measurement areas

- RS232 interface: Transfer measurement protocols to a PC

- Multi-point material correction function to optimize measurement results

Are you looking for an easy-to-use instrument to measure the depth of surface cracks in metals that you have detected, for example, using magnetic particle testing (MT) or penetrant testing (PT)?

Do you want to evaluate the extent, orientation, or inclination angle of a crack, enabling you to make decisions about possible rework of the test piece?

Or do you want to monitor the growth of a crack as operating time increases? Then we recommend the RMG 4015 crack depth meter.

Advantages of RMG

Because alternating current (AC) is used, the measurement utilizes the skin effect: The current is forced to flow close to the surface, closely following the contour of the crack.

An additional advantage: Due to the low pulsating current, the required result is achieved, and any burnt contact points on the specimen can be avoided. The small, battery-powered handheld unit combines current generation, measurement technology, and microprocessor-based evaluation, and it can be easily taken to any worksite.

RMG is optimized for use on steel, iron, and austenitic materials. A material-specific calibration adapts the instrument to the distinct electrical and magnetic properties. For this purpose, RMG offers different calibration methods: In the simplest case, it is sufficient to perform a comparison measurement on a crack-free area of the specimen. Higher precision is achieved by means of a comparison measurement on a reference notch with a depth close to the expected crack depth. A multi-point calibration over reference notches of varying depths covering the entire measuring range leads to the best results.

The RMG 4015 crack depth meter can also be used on copper, brass, aluminum, or other metallic materials (though the measuring range and resolution may be reduced). For challenging applications, it is possible to adapt a special probe to specific requirements (on request).

Measuring Technique

The RMG uses the “potential drop” method with alternating current:

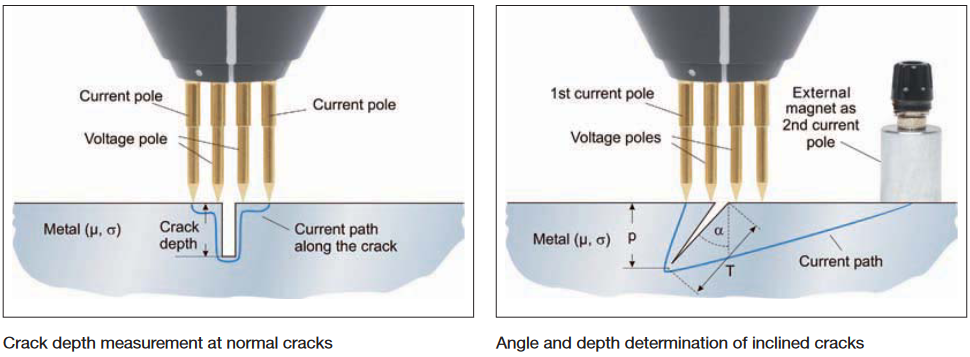

Via two current electrodes placed to the left and right of the crack, a constant AC current is introduced into the workpiece. The voltage drop between two additional electrodes placed to the left and right of the crack is proportional to the crack depth.

Conditions for a reliable measurement: The electrical and magnetic properties of the material around the crack are sufficiently homogeneous.

The width of the crack has almost no influence on the measurement (Fig. left). For measuring the depth of inclined cracks, the frequency of the alternating current is automatically reduced so that the electric current covers a larger area in the workpiece. Depending on the position of the external current electrode (placed either on the left or right side of the crack), different voltage drops occur, which are used to calculate the angle B (Fig. right).

Versions (Probes)

Probes for the RMG 4015 Crack Depth Meter (Order No.: 4015.003)

Standard Probes

- Crack Depth Probe RMSQ 0° (Order No.: 4418.001)

- Crack Depth Probe RMSL 0° (Order No.: 4416.001)

- Crack Depth Probe RMSQ 90° (Order No.: 4417.001)

Special Probes for measuring inclined cracks:

- Crack Depth Probe RMSL-S 0° incl. external magnet and cable (Order No.: 4421.001)

- Crack Depth Probe RMSL-S 90° incl. external magnet and cable (Order No.: 4420.001)

| Title | Type | Size | Download |

|---|---|---|---|

| RMG-4015-e-06_07_Karl-Deutsch.pdf | 371.13KB | Download |

_copy (1) (1)/assets/images/header/trustpilot.png)