What is Ultrasonic Testing?

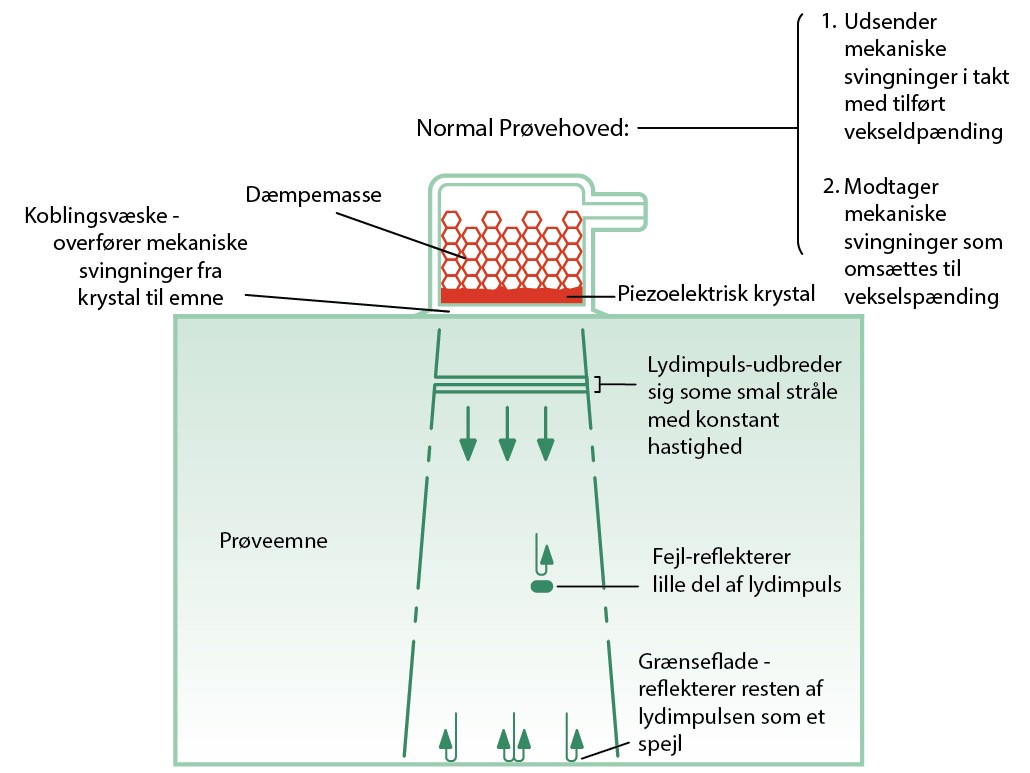

Ultrasonic Testing (UT) based on the pulse-echo method can be simply described as a kind of material radar.

A very short pulse of very high-frequency mechanical vibrations is sent into the material.

They are of the same nature as sound waves but cannot be heard, so they are referred to as ultrasonic vibrations.

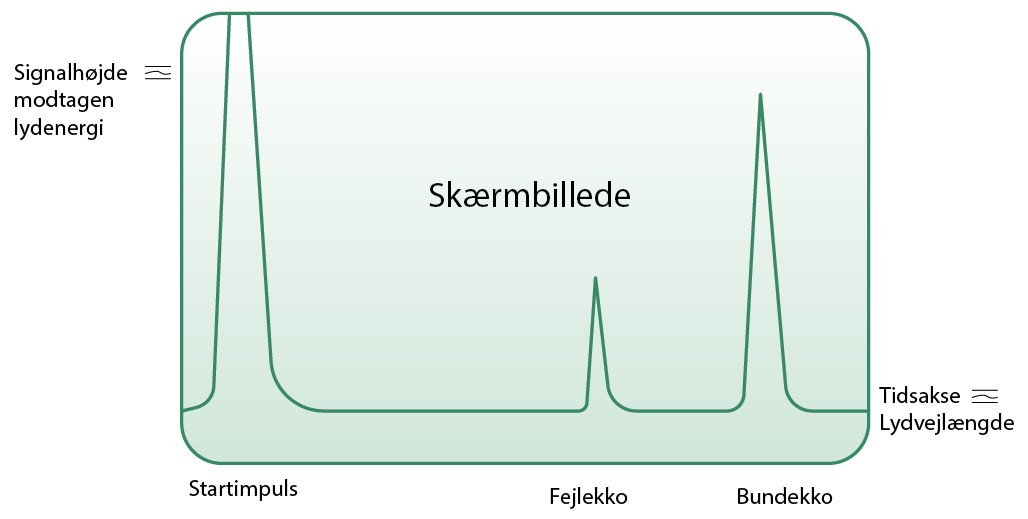

The pulses propagate through the material as a relatively narrow beam until they reach an interface, for example the opposite surface of the test piece or an internal flaw. From there, they are fully or partially reflected back to the transmitter, which now functions as a receiver. The time between the sending of a pulse depends on the distance traveled, since the propagation speed is constant for a given material type.

If a pulse is sent perpendicularly through a plate and the travel time is measured, the plate thickness can be calculated. This principle underpins how the Ultrasonic Thickness Gauge works.

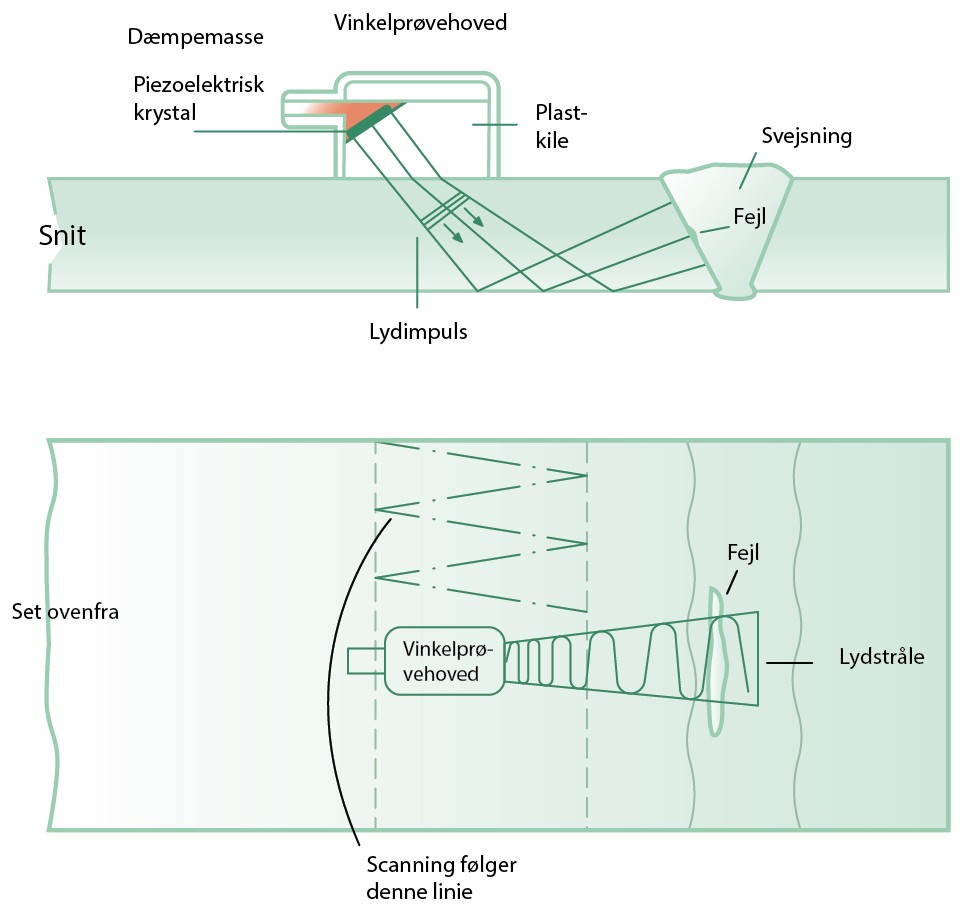

If you want to locate internal flaws in a component, in addition to the distance covered, you need to know where the sound pulse originates and in which direction it has traveled. Larger flaws are mapped by moving the transducer (the device that sends and receives the sound pulses) across the surface of the material.

This scanning process follows a certain pattern.

The emission is repeated so many times per second that the instrument display shows what appears to be a stationary image. Nevertheless, it occurs at intervals long enough that any reflected pulses—which can sometimes bounce back and forth many times in materials with smooth surfaces and low attenuation—will have completely disappeared before the next pulse is sent.

This system is called the pulse-echo method and can be used both to determine material dimensions (when the sound velocity is known) and, conversely, to determine the sound velocity when the traveled material thickness is known.

The History of Ultrasonic Testing:

Testing with sound vibrations has been in use for many years, for example by listening with the ear to the tone a piece (coin, cup, wheel tire) emits when struck in a suitable manner.

During the Second World War, electronics developed significantly, and among other things, the radar system was invented.

After discovering that wafers of certain crystals (e.g., quartz) produced mechanical vibrations when an alternating electric voltage was applied to their surfaces, it became possible to manufacture the first ultrasonic devices operating on the pulse-echo principle. Fully functional instruments using this principle came onto the market in the early 1950s. They have since been extensively developed for many specialized applications but still function on essentially the same principle.

Nowadays, there are quite small battery-powered thickness gauges that can measure metallic items between 1 and 100 mm in thickness or more.

What is Thickness Measurement?

Thickness measurement is one of the most commonly used methods for checking and testing pipes, tanks, etc.

An ultrasonic signal is emitted, and the returning echo is monitored to determine the thickness of a component. It is very frequently used in the oil, gas, and chemical industries.

In condition surveys on equipment in operation, ultrasonic testing is particularly used for thickness measurement, by which reductions in wall thickness caused by erosion (mechanical wear) or corrosion (chemical wear) can be determined.

During condition monitoring, thickness measurement can also be used to detect structural changes that can occur in some materials under high temperatures and, for example, from hydrogen that can penetrate the material.

Thickness Measurement with USM Go+

_copy (1) (1)/assets/images/header/trustpilot.png)