What is Eddy Current Testing?

Eddy Current Testing (ECT) is an electromagnetic inspection method that can be used on all electrically conductive materials. Sometimes referred to as “inductive testing.”

The method is used for:

- Crack detection

- Corrosion and thickness measurement

- Material sorting

- Detection of heat-affected zones

- Measurement of coating or plating

- Measurement of electrical conductivity

- Metal detection

Advantages

The advantages of Eddy Current Testing compared to other methods, for example crack detection, include the following:

-

Fast to apply, since no pre- or post-treatment of the test object is required.

-

Does not require direct contact between the test coil and the test object, which means the method can be used on painted surfaces. Furthermore, it is possible to use the method underwater.

-

Inexpensive to use, as no materials are consumed.

-

When inspecting larger series, the method can be automated.

Eddy Current Testing

Originally, the equipment in principle consisted of the following three components: a generator, a test coil, and a registration device, for example an ammeter or an oscilloscope.

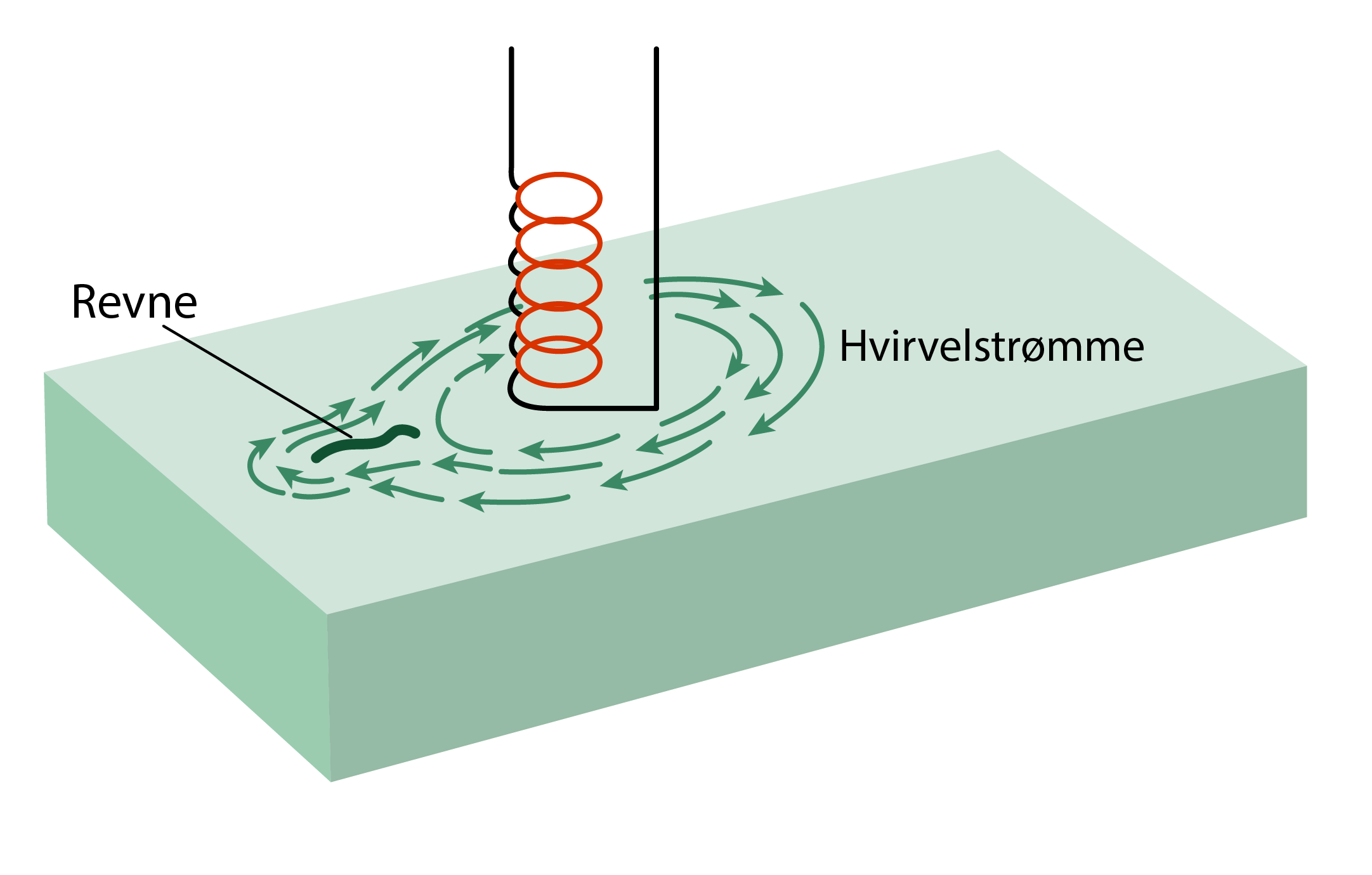

A generator produces an alternating current that flows through the test coil. When this current passes through the test coil, a magnetic field is created around the coil—the primary field. This magnetic field induces eddy currents in the test piece when the test coil is held over it. At the same time, the eddy currents in the test piece will induce a magnetic field in the test piece—the secondary field—which is opposite to the primary field. The strength of the secondary field compared to the primary field depends, among other things, on the electrical and magnetic properties of the test piece.

If an ammeter is connected to the test coil, the ammeter will show a standard reading, which reflects the condition of the test piece. If the ammeter is zeroed, it will remain at zero when the test coil is moved across the test piece, provided the eddy currents can flow unchanged in the material.

If the currents change value, the strength of the secondary field will also change. This will then change the strength of the primary field in the test coil, thereby changing the current through it, which will register on the ammeter.

The value of the eddy currents is influenced by changes in the electrical and magnetic properties of the test piece, cracks or inclusions in the test piece, and the distance between the test coil and the test piece. These factors are utilized in Eddy Current Testing.

Eddy Current Testing of Weld Seams

Eddy Current Testing with WeldCheck from Ether NDE

Eddy Currents Historically:

Between 1775 and 1900, scientists such as Coulomb, Ampere, Faraday, Ørsted, Arago, Maxwell, and Kelvin discovered and formulated most of the knowledge we have today about magnetism and electromagnetism. This knowledge forms the basis for the principles of the electromagnetic Non-Destructive Testing (NDT) used today.

In 1824, Arago discovered that the oscillations of a magnetized pendulum were greatly dampened when it approached a non-magnetic, electrically conductive material. In 1820, Ørsted discovered the magnetic field that arises around a conductor carrying a current. In the same year, Ampere found that two equal currents running in opposite directions in two closely spaced conductors cancel out the magnetic field around the conductors. Faraday discovered the principles of electromagnetic induction in 1831. Maxwell compiled these and other discoveries in a two-volume work published in 1873. Maxwell’s equations for magnetism and electromagnetism are still used as the foundation for research in these areas.

It took many years before this knowledge was applied to non-destructive testing (NDT). In the 1930s and 1940s, great progress was made in this field. One of the driving forces behind this was the German Dr. Förster. During that period, he conducted many groundbreaking experiments and formulated the theories for Eddy Current Testing, and also developed entirely new types of equipment for this testing.

Since Dr. Förster built his first equipment, advances in Eddy Current Testing have been rapid. Especially between 1975 and 1985, development was enormous, both in terms of equipment and in the application of the method. In the mid-1980s, the first generation of microprocessor-based equipment appeared on the market. This equipment made it possible to store data such as inspection data, reference flaws, indications, etc.

_copy (1) (1)/assets/images/header/trustpilot.png)