ECOlogical Design

STRUCTURIX M ECO meets environmental expectations with:

- Revolutionary cascade fixing system, which reduces the amount of silver in the effluent by a factor of 5 to 10.

- Reduced fixer replenishment when STRUCTURIX ecoFix is used.

- Economical water and power consumption.

- Infrared drying system that reduces the amount of heat generated in the darkroom to a minimum.

- Optimal replenishment system as a result of scanning the film surface.

- Intermediate wash, which ensures that there is virtually no carry-over of developer, keeping the fixer bath in optimal condition. This system also prevents processing faults on the film.

- Design for recycling

Extra attention has been paid to the choice of materials in order to improve recyclability. Materials or components that could disturb the recycling process are easily removable. A Recycling Passport (RP) and an Equipment Information Sheet (EIS) are available.

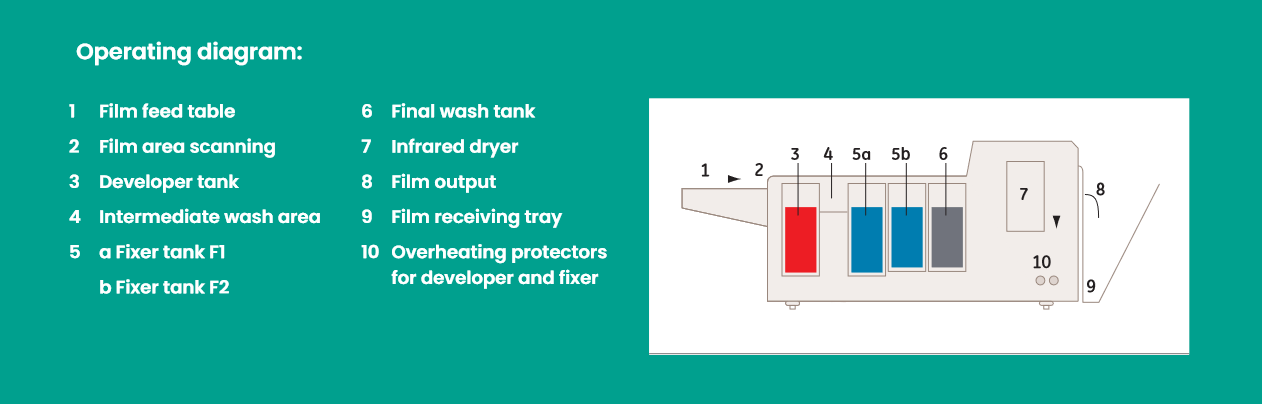

Accurate replenishment

The film surface area is measured accurately at the entry by 5 detector rollers. This unique scanning of the film area ensures a precise, economical and environmentally friendly replenishment operation and reduced replenishment rates.

Minimal operating costs

The accurate replenishment, as described above, results in low chemical consumption. In addition, only an environmentally justified volume of water is used during film processing, and the power consumption is particularly low thanks to the infrared drying system.

Tailored features

Compact size

Takes up only 0.56 m² of floor space.

Well-thought-out, lightweight construction

Constructed from stainless steel, aluminium and PVC to be corrosion-resistant, strong, lightweight and durable.

Easy to use

Built with an automatic start/stop function. Film detection with five scanning rollers allows intelligent and economical replenishment depending on the processed film surface. The removable control panel provides visual reference for all process parameters (temperature, drying settings).

An OK light indicates when the next film can be inserted.

Easy to service

Lightweight aluminium side covers allow quick access to the machine. Circulation pumps and racks are easy to remove, clean and service. The external water and chemical connections ensure efficient and separate disposal of the liquids.

Light-tight cover

The standard light-tight cover allows the operator to perform other tasks while the film is fed into the STRUCTURIX M ECO film processor. It also prevents dust particles from entering the processor, avoiding scratches on the film.

Globally adaptable

Supplied with advanced electronics. The worldwide "plug and play" function makes it possible to adapt it to any standard power outlet, accommodating all voltages globally.

_copy (1) (1)/assets/images/header/trustpilot.png)